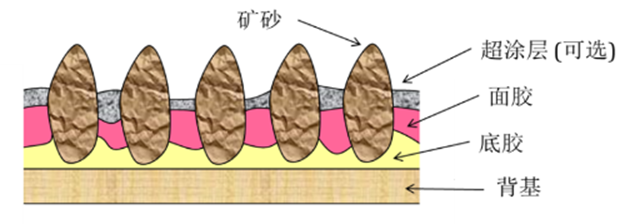

Sandpaper is a commonly used consumable for polishing and grinding, and is indispensable for various mold models such as mobile phones, cars, and wooden products; It belongs to a type of coated grinding tool, called flexible grinding tool; The wear resistance of sandpaper is very important, determining the quality of sandpaper.

Sandpaper composition

The composition of sandpaper is mainly determined by three elements: backing, adhesive, and sand particles (abrasive).

Back base

1. Buki

It has good extensibility and is mainly used for metal and wood polishing. It can be divided into 5 grades from light to heavy: F, L, J, X, and Y.

(1) Blended fabric (code B), strong enough and not easy to break;

(2) Pure cotton (code C), with good shaping and water absorption ability;

(3) Polyester cloth (code D) has good hardness and is not easily deformed, so it is also not easy to stretch;

2. Paper based

Compared to cloth, it has better flatness and sanding effect, so it is mainly used for polishing paint surfaces. However, it is prone to breakage and has poor compressive performance. From light to heavy, it can be divided into 7 levels: A, B, C, D, E, F, and G.

(1) Dry grinding: using base paper

(2) Water mill: using kraft paper

3. Composite base

Composed of fabric and paper, with properties between the two.

Sand particles (abrasives)

1. Aluminum oxide: also known as brown corundum, usually with a red sand surface. It has good toughness, excellent crushing resistance and hardness, wear resistance, and the sand particles are in a △ shape. During the polishing process, the peak will gradually become round.

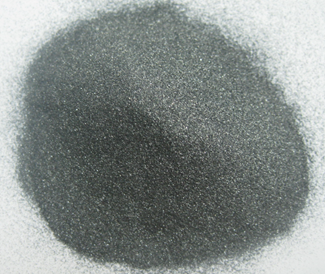

2. Silicon carbide (C): It has a black sand surface with sand particles in a △ shape, which has good self sharpening and crushing properties. Therefore, it has good heat dissipation and cutting properties, and can maintain its peak during the polishing process, but the triangle will gradually shrink.

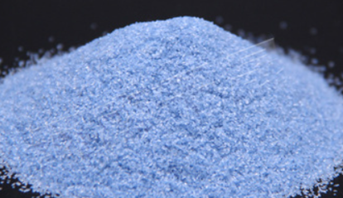

3. Zirconium corundum (Z): It has a blue sand surface, good hardness and flexibility, and is wear-resistant and has good machinability.

4. White corundum (W): It is a white coating on sandpaper that is anti-static and anti clogging. It is generally used for polishing paint and metal.

Sandpaper application

1. The cutting power of worn sandpaper will decrease, which is actually equivalent to one size higher sandpaper, causing an increase in heat generation.

2.The greater the pressure applied to the sandpaper, the more severe the wear and tear of the sandpaper, and the higher the heat generated, which can easily burn the surface of the wood. Therefore, only light polishing is needed to effectively polish and extend the life of the sandpaper.

3. Avoid using only one grit sandpaper throughout the entire process, as this results in very low power consumption.

Copyright © Zhenjiang Pangea Imp & Exp Trade Co.,ltd. All Rights Reserved | Privacy Policy | Blog